I had always planned on a set of oars for Nephi’s Courage. I drew oar locks into the plans, and I purchased an inexpensive set of nylon oarlocks from Duckworks when I made my big order from them, and I even installed the oar locks when I built the boat. It turned out to be a good thing too. When I first launched the boat I didn’t have the clam cleats yet for the jib (I forgot them in my order to Duckworks), and so I used the oar locks as a fairlead for the jib as they are mounted in approximately the right place.

What I did not do was actually purchase oars. My alternative power source all of last season was a tiny orange collapsible paddle that my neighbors gave me (thanks Karl). Several times last year I was becalmed enough that I actually had to use that paddle. I would lean against one of the air boxes and paddle one handed, while trying to steer the boat with my foot. This also provided part of the motivation for a “tiller tamer” mechanism that could lock the tiller in place, but I hope to write about that later.

Perhaps the worst part about not having oars was that it required me to get wet up to the waist every time I launched. Nephi’s Courage doesn’t require very much water to float, but the prevailing wind where I launch requires that I launch right into the wind. Since I can not really make headway until the leeboard gets down a foot and a half, or so, I ended up having to pull my boat out quite a ways from the beach before climbing into the boat. I tried using the paddle but without a lanyard to hold up the rudder blade, or at least a workable way to keep the tiller straight, these attempts just made me look ridiculous.

I may be a fat guy, in a tiny, obviously homemade (read ugly) wooden boat, but flailing around ineffectively with a orange plastic toy paddle in a few inches of water is too much for even me.

And no, I don’t have any pictures of my attempts. I didn’t have any free hands for filming.

Anyhow, oars have been on my wish list since I first started dreaming about the boat, and they were definitely something that I wanted before boating season rolled around again. Unfortunately, buying oars was out of the question. My wife is willing to put up with my pdracer fixation as long as it doesn’t cost actual money. I was able to find 6 foot boat oars for as little as $30 apiece, but $60 was just outside of my mad money price range. Besides, I own a copies of both Boatbuilding for Beginners (and Beyond) and Ultrasimple Boat Building and both of these books have plans for the exact same set of oars.

That definitely seemed like a sign to me. The fact that the pine boards that I needed to build these oars cost less than $6 sealed the deal. I picked up a pair of 8 foot boards at Lowes, and headed for home.

It then took me a couple of days to get around to actually starting on the oars. In that time the boards warped. That made making them even more fun. However, I was pretty sure that I could still get something useful out of the boards. So I set to work.

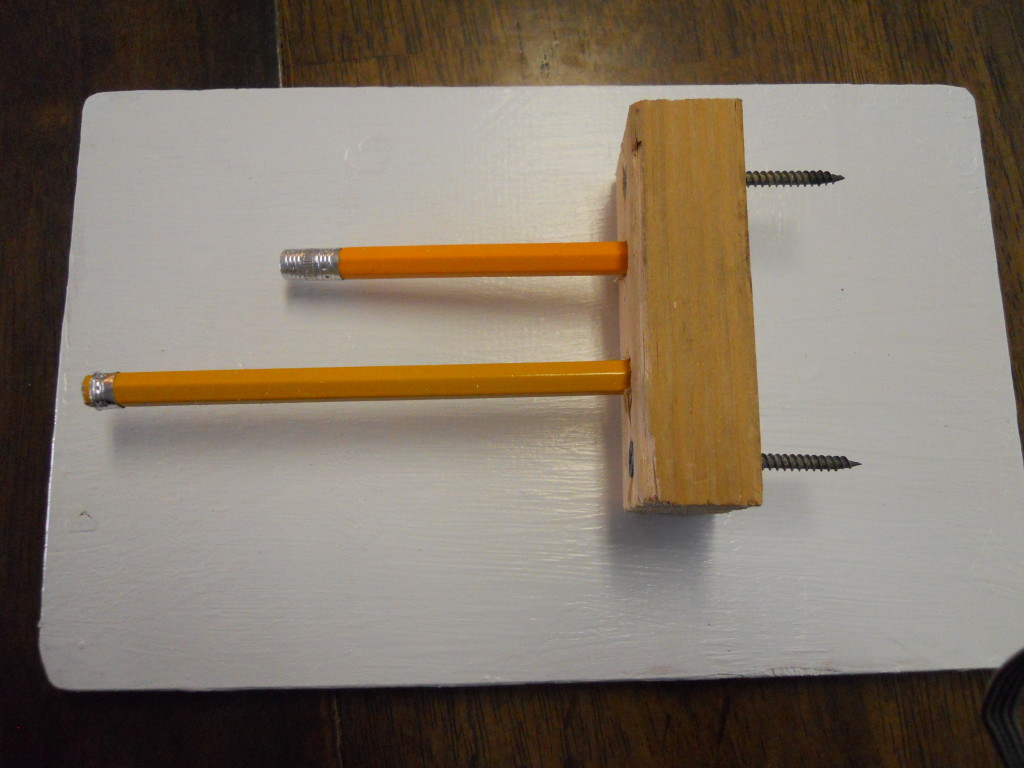

Once the oars were glued up the real work began. I don’t have any fancy wood working tools. I have a block plane I purchased from Harbor Freight, a rasp that I picked up from Lowe’s, and an Old Hickory butcher knife that takes a great edge. That, along with a spar gauge that I made out of a piece of wood and a pair of sheetrock screws are all of the tools that I used to shape the oars.

Despite my primitive tools carving the oars to the basic shape was actually pretty easy. I am surprised, for example how quickly the block plane turned the shaft of the oars into a cylinder (well, I left a bit of oval shape to the cross section on purpose).

Once I got the oars shaped, and made sure that they fit the oarlocks I had ordered, I needed to decide how I was going to finish them. Both Michalak and Atkin advise wrapping 8 inches just below the square part of the loom with synthetic twine and then varnishing everything (including the twine). I am not interested in varnish. Paint is cheaper, and it covers the ugly better. I don’t have the patience to build beautiful things when useful ones will suffice.